SnapFrames Guide

Tutorial: Generate Your Frame

Enter Your Build Plate Size

Select your 3D printer's build plate size. Generated frame components will be automatically sized to fit your build plate, with parts split as needed for larger frames.

Smart Orientation is enabled by default. It automatically rotates pieces 45° diagonally when doing so reduces the number of seams in your frame. If diagonal orientation doesn't reduce piece count, it stays orthogonal for better bed packing.

Set the Frame Interior Dimensions

Enter the exact interior opening you want for your artwork or photo. The frame will be generated to these interior dimensions. Generate a frame about 0.2mm larger than your artwork for an easy fit.

Choose Your Frame Type

Picture Frame

Best for traditional photo and glass displays, HueForge 3D prints, and other thin artwork up to 6mm thick.

- Artwork secured from back with removable 3D printed prongs

- Optional glass/plexiglass sheet for protection

3D Art Frame

Great for 3D cityscapes, canvases, and floating-style displays that may extend above the frame.

- Artwork glued to the flange

- Ideal for Micropolitan 3D map art

- No lip over the artwork

Floater Frame

A deep-profile frame for canvas wraps and thick artwork. Creates a floating effect with visible space between the art and frame edge.

- Recessed ledge for canvas and thick pieces

- Art appears to float within the frame

- Tall frame walls for a gallery look

Select or Design Your Frame Style

Choose from wood grains and preset patterns, or design your own frame pattern.

Smooth & Wood Grains

Choose Smooth for a clean face, or select a wood grain pattern. When a wood grain is chosen, Advanced Wood Options can be configured to customize the grain density, structure, and knot count for that preset wood species.

Preset Designs

Pattern presets can be edited and saved as new customized patterns by clicking the pencil icon on them.

Pattern Composer (Beta)

Create your own 3D relief patterns to apply to the frame face. Inside the Pattern Composer, you'll find:

- A library of seamless images to choose from

- Option to upload your own images

- Draw custom edge profiles (rounded corners, moulded shapes)

- Layer-based editing with opacity and ordering controls

- Directional patterns can be rotated on each edge for uniformity

How it works: Images act as heightmaps — light (white) areas are elevated, dark (black) areas are embossed. Seamless patterns are recommended for a continuous look.

My Designs & Community Designs

Save your custom patterns to My Designs for reuse later. When signed in, designs sync to your account and can be accessed from any device. Browse the Community Designs gallery to find and use patterns shared by other users, or share your own creations with the community.

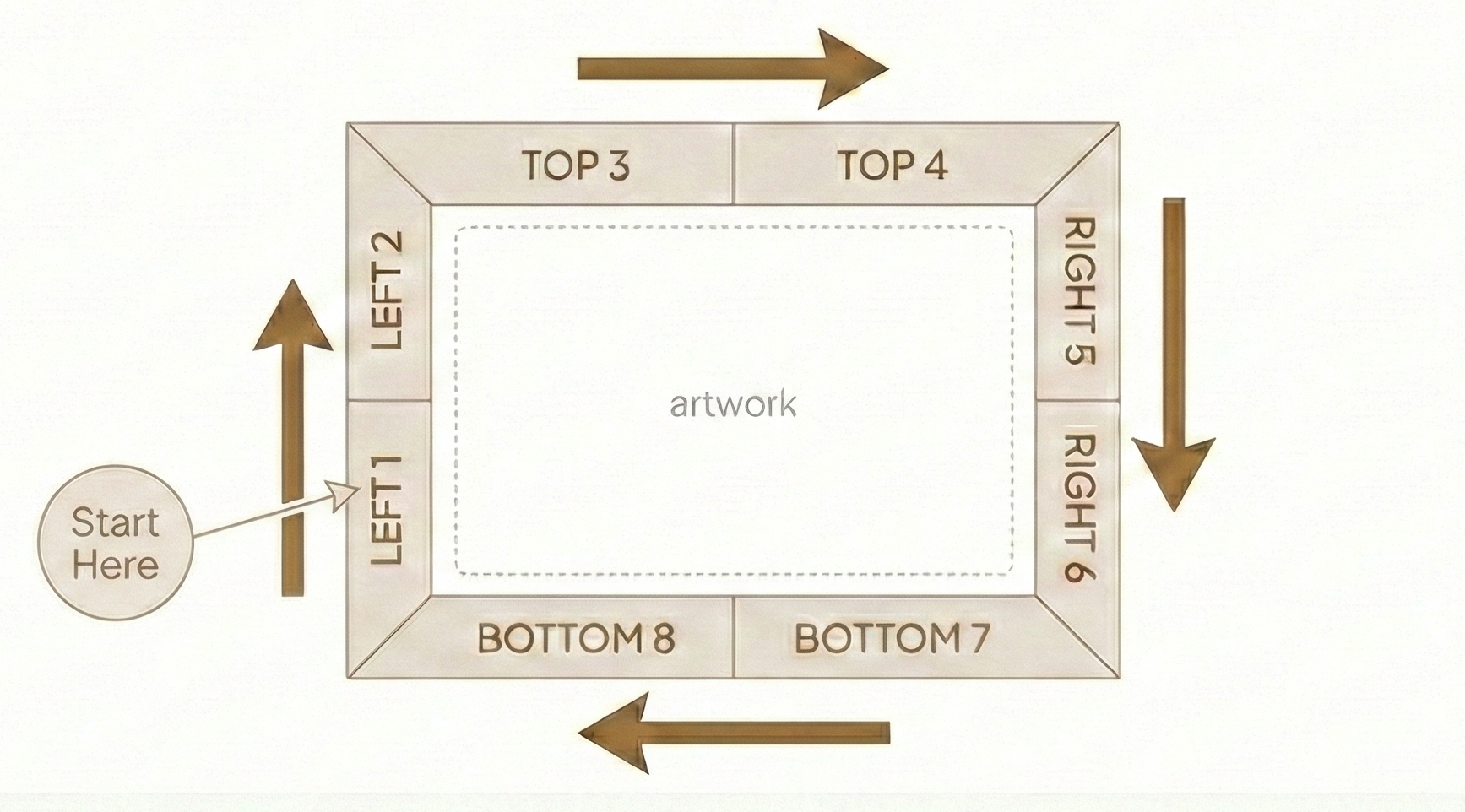

Configure Part Labels

Add subtle protruding text to the back of each frame piece for easy identification during assembly. Labels are raised from the surface and appear on the back face (opposite the textured/veneered side).

Standard Labels

The default option includes part numbers, frame dimensions, and SnapFrames branding on each piece.

Part numbering: Each piece is labeled with its edge (LEFT, TOP, RIGHT, BOT) and a sequential number. Numbering starts at #1 on the LEFT edge (bottom piece) and continues clockwise around the frame.

Custom Labels

Customize what appears on your labels. Toggle part numbers and dimensions on or off, add your own custom text (like your brand name or a message), and upload a logo image.

Logo editor: Click the pencil icon to open the logo editor where you can crop your image (free or square), adjust brightness and contrast, and toggle invert. The "Invert" option is enabled by default, which works best for dark logos on light backgrounds. The preview shows the heightmap where brighter areas become more raised on the printed frame.

Text Size and Height

Adjust the Size slider to scale text and logos relative to the frame face (75%-200%), and the Height slider to control how much the text protrudes from the surface (0.05-0.5mm).

Tip: After generating, check the 3D Preview to confirm your labels display correctly. Smaller frames may need reduced text size to fit all the content.

Generate & Preview

Generate your frame and preview it in the 3D Frame Preview before downloading. Use the Sample button to generate a small test piece to check texture and color.

Add Accessories

Before downloading, expand the Accessories section to optionally include additional components.

Backer Plate

A solid backing piece that snaps onto the frame. Choose with or without an integrated kickstand for tabletop display. The kickstand is automatically sized for stable support.

Mat / Passepartout

Add a decorative border around your artwork. Customize the opening size to create wider or narrower margins. Print it or use it as a template for cutting traditional mat board.

Embossed Note

Add a personalized message that gets printed on the backer plate. The text can be visualized in the 3D preview and adjusted for font size and protrusion depth.

Download Your Files

Click Download STL Files to get a ZIP containing all your frame parts, clips, prongs (if applicable), accessories, and a settings file for re-importing later.

Slice & Print

Unzip the folder and import all STL files into your slicer software.

- When prompted to load files as a single object, click No

- Right-click on the build plate and click Arrange to auto-arrange parts

- Parts are already in the correct orientation (faces print vertically for max detail)

Print Settings

SnapFrames print well with the default profile on most FDM printers. Use standard wall counts and infill settings (15-20%).

Arachne wall generator mode is recommended if your slicer allows it. This handles variable-width extrusions for sharper textures and more accurate corners.

Layer Height

We recommend a 0.20mm layer height for most frames. For very fine textures or high-detail patterns, 0.12–0.15mm will provide the best results.

Materials

Recommended

PLA & Matte PLA

Best overall choice for a premium, non-glossy finish. Darker colors help to hide the seams

Silk PLA (Gold / Bronze)

Great for accent strips or decorative features

PETG

For extra strength and durability

Not Recommended

Wood PLA

Tolerances are less consistent and may result in wider gaps at seams

Recommended Filaments

Matte Black PLA

Best for hiding seams

Matte White PLA

Clean, modern look

Light Brown Matte PLA

Great for wood grain

Matte Chocolate PLA

Great for wood grain

Matte Wood Brown PLA

Great for wood grain

Metallic Gold PLA

Great for accent frames

As an Amazon Associate, SnapFrames earns from qualifying purchases.

Recommended Accessories

These accessories pair well with your 3D printed frames for a polished, professional result.

Clear Acrylic Sheets

Shatter-resistant alternative to glass. Easily scored and snapped to size with a utility knife. Use in front of artwork for protection (like traditional picture frame glass) or behind photos as a rigid backer.

Mat Board

Cut custom mats using the 3D printed mat as a template. Available in multiple colors to complement your artwork.

As an Amazon Associate, SnapFrames earns from qualifying purchases.

Design Tricks & Advanced Tips

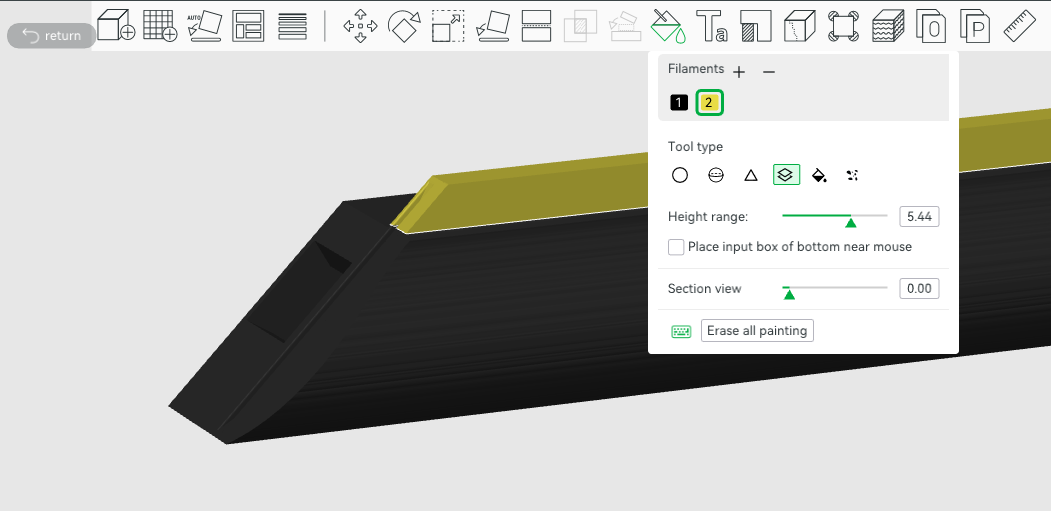

Multi-Color Frames (Even Without a Multi-Color Printer)

Assign a different color at a specific layer height for accent stripes or layered face details.

Single-color printers: Manual filament swaps at designated layers

Multi-color printers: Automatic swaps with minimal waste

One-Piece Frame

Check One-Piece Frame in Step 6 to generate a single unified STL of the entire frame printed flat. The Full Frame tab in the 3D Preview shows the assembled result, and a dedicated download button exports the file.

How It Works

Check One-Piece Frame in the Generate section to export a single unified STL with all four edges joined at mitered corners — no snap connectors or clips needed. The frame prints flat (face-up), so part labels are omitted. You can generate this alongside Snap-Together and/or Sample Corner.

Best For

Seamless frames with no snap-together joints. Great for multi-color prints since the textured face prints horizontally (facing up), allowing filament swaps at specific layer heights for a two-tone texture effect. Also ideal for quick small frames that need no assembly or clips. Only available for frame sizes that fit on your build plate as a single piece.

Trade-offs

Only available when the assembled frame fits on your build plate. Fine relief details may be less sharp compared to vertical printing (limited by nozzle width vs. layer height resolution). Depending on the Frame Style, supports may be needed for overhangs when printing flat.

Large Frame Tips

- Test small before printing large — use Sample mode to verify texture and color

- For large frames with many edge pieces, consider reinforcing joints with glue

- Mount the frame around chipboard or rigid backing material for added stability

- Hang from the backing rather than the frame parts for very large frames